Engineering team specialized in providing customized solutions.

We guarantee problem-solving in Industrial Automation, ensuring optimal performance and continuous innovation.

International Presence

With proven experience in Canada, United States, and Colombia, we offer industrial automation solutions for projects anywhere in the world

Proven Experience

Successful projects in 3 American countries

Global Reach

Capability to work at any location

No Boundaries

Your project, wherever you are

Experience that Backs Us

Over a decade building industrial automation solutions

Years of Experience

We bring solid expertise in the industry

Projects

Service, commissioning, troubleshooting, start-up

VFDs

Services, commissioning, repair, start-up

Our Services

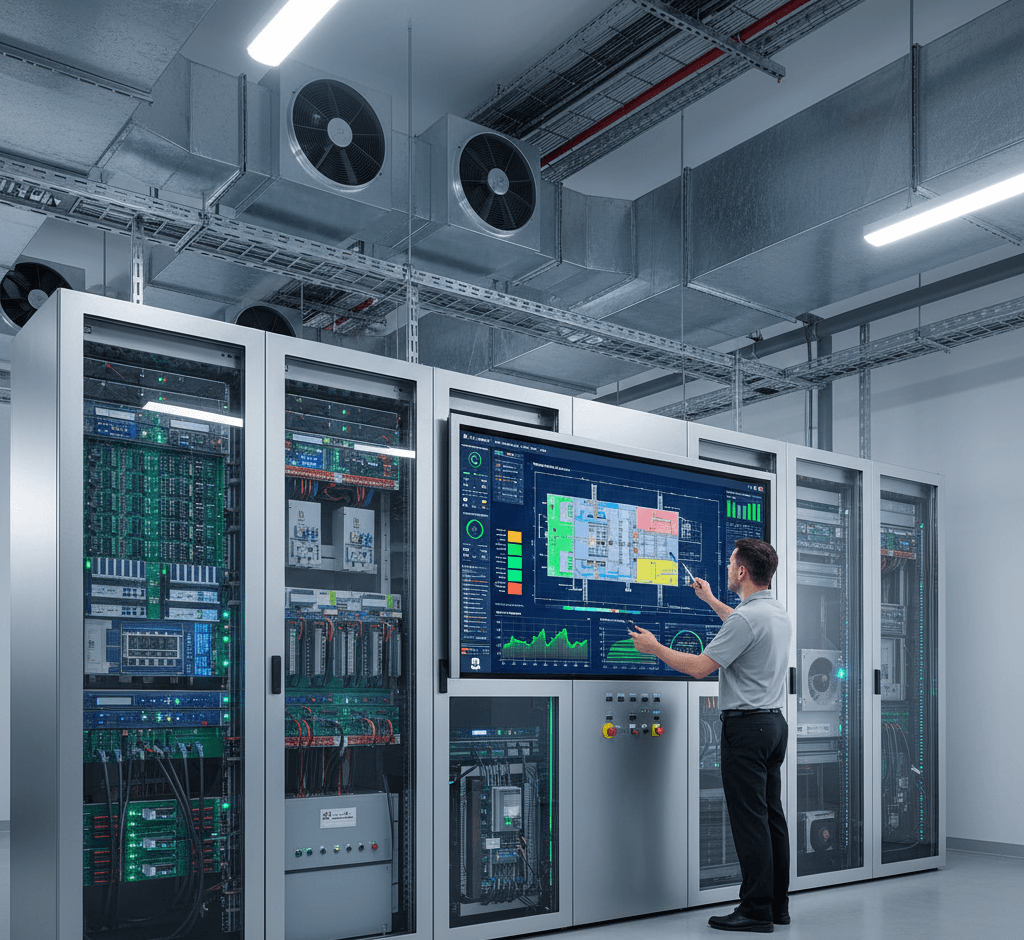

Transforming industrial operations through innovative automation solutions tailored to your specific needs

Troubleshooting

Specialized Problem Solving

Low Voltage Control Panels, VFD's, PLC's, HMI, SCADA diagnostics and resolution for optimal system performance.

Key Features

Custom Solutions

We offer any type of service tailored to your industrial automation needs. From custom integrations to specialized projects.

Need a custom solution?

Featured Projects

Over 10 years of delivering excellence across Canada, USA, and Colombia. See our transformative automation solutions in action.

Vancouver Airport Fuel Delivery

Confidential

350 HP / 600VAC ABB Variable Frequency Drive implementation with Pump Smart System for optimized fuel transfer operations and energy efficiency.

Automation

Various Facilities

Advanced Building Management System (BMS) for industrial automation with multi-zone control, energy monitoring, and predictive maintenance capabilities.

Pie Freezer Line

Confidential

Complete support and commissioning of industrial pie freezer line. Advanced PID temperature control, hydraulic pressure management, conveyor tension monitoring, and torque/speed optimization systems.

Boiler Water Plant

Carvajal, Pulpa y Papel

Comprehensive maintenance plan and technical support for industrial boiler water treatment systems. Ongoing reliability-centered maintenance program.

KKCC - Reverse Osmosis Plant

KKCC

Turn-key reverse osmosis water treatment plant. Complete troubleshooting, PLC programming, commissioning and start-up services for industrial water purification system.

Runnability Tester Upgrade

Smurfit Kappa

Turn-key quality assurance laboratory automation project. Complete instrumentation, data acquisition systems, and runnability tester upgrade for paper quality control.

Ready to start your project?

Get in TouchOur Allies

Leading companies that trust our expertise

We are proud to collaborate with organizations across diverse industrial sectors, providing world-class automation solutions that optimize processes and drive measurable results.

Our experience covers multiple leading brands in industrial automation, including Siemens, Rockwell Automation, ABB, Schneider Electric, and Yaskawa, ensuring reliable solutions compatible with global standards.

Over 50+ successful projects completed in the last 10 years

PID Control in Real Time

Experience how an industrial automatic control system works

Control System

Target Level (Setpoint)

PID Parameters

PID Control: The system automatically adjusts the valve to maintain the tank level at the desired value, using proportional, integral, and derivative control algorithms.

Ready to take your industrial

operation to the next level?

Leave your details and our team will contact you shortly

By submitting this form, you agree to West Automation contacting you to discuss your industrial automation needs. We are committed to protecting your privacy and will not share your information with third parties.